PostTime:2/2/2026

Focusing on the forefront of technology and addressing the demands of the times, the courses of Guangdong Technion - Israel Institute of Technology (GTIIT) provide students with a solid foundation in science and engineering and strengthen their core disciplinary competencies through robust professional training and innovative instructional design. These courses not only forge students' hardcore capabilities but also ignite their enduring passion for exploring scientific truths as they unlock new realms of knowledge.

From this issue, the "GTIIT Course Exploration" series will take you into popular courses filled with hands-on practice and engaging fun among students.

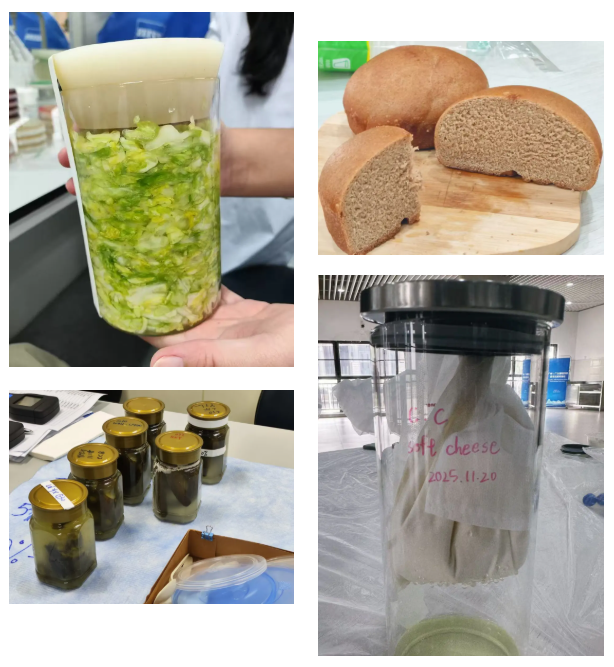

Food Microbiology (Instructor: Yigal Achmon)

From hands-on exercises in the lab to immersive experiences on production lines, emphasizing practice and exploration, the course brings knowledge out of textbooks and into real life. Both inside and outside the classroom, students decode the mysteries of microorganisms, establish a basic understanding of food production processes which utilize microorganisms, learn about foodborne pathogens and food spoilage, while also mastering the principles of food preservation, identification and prevention of microorganisms in food, along with risk assessment methods.

The course also includes on-site visits to food enterprises. During the study tours, students integrate classroom knowledge with frontline production practices, apply experimental skills to analyze real products, gain an in-depth understanding of production standards and mechanized operations, learn about corporate management strategies, and are further inspired to reflect on existing standards, factory design, production processes, etc..

In the lab sessions, we got to make yogurt, kimchi, pickles, wine, and bread, studying the fermentative role of microorganisms while doing so—it was both fun and educational. The course also organized visits to candy, rice wine, beef ball, and seafood processing factories, linking lab knowledge with industrial practice in an engaging way. (Chen Yizhou, 23BFE)

This course is closely connected to daily life and highly engaging. It covers a variety of topics with hands-on experiments on food microbiology conducted every two weeks, including making yogurt, sauerkraut, red wine, bread, and more. We even investigated the microbiological conditions of water sources around the campus. At the end of the course, we further deepen our practical experience through activities such as enterprise visits and safety testing of various products. I visited a company specializing in deep processing of quick-frozen seafood, where I learned about the operations of the factory, the setup of the monitoring system, and the methods for controlling microbial testing. Each group was required to deliver a 15-minute presentation and submit a report based on the visit. The assessment methods for this course are also diverse, including final exam, lab reports, quizzes, group presentation, teachers' evaluation, etc.. (Tan Zhenyuan, 23BFE)

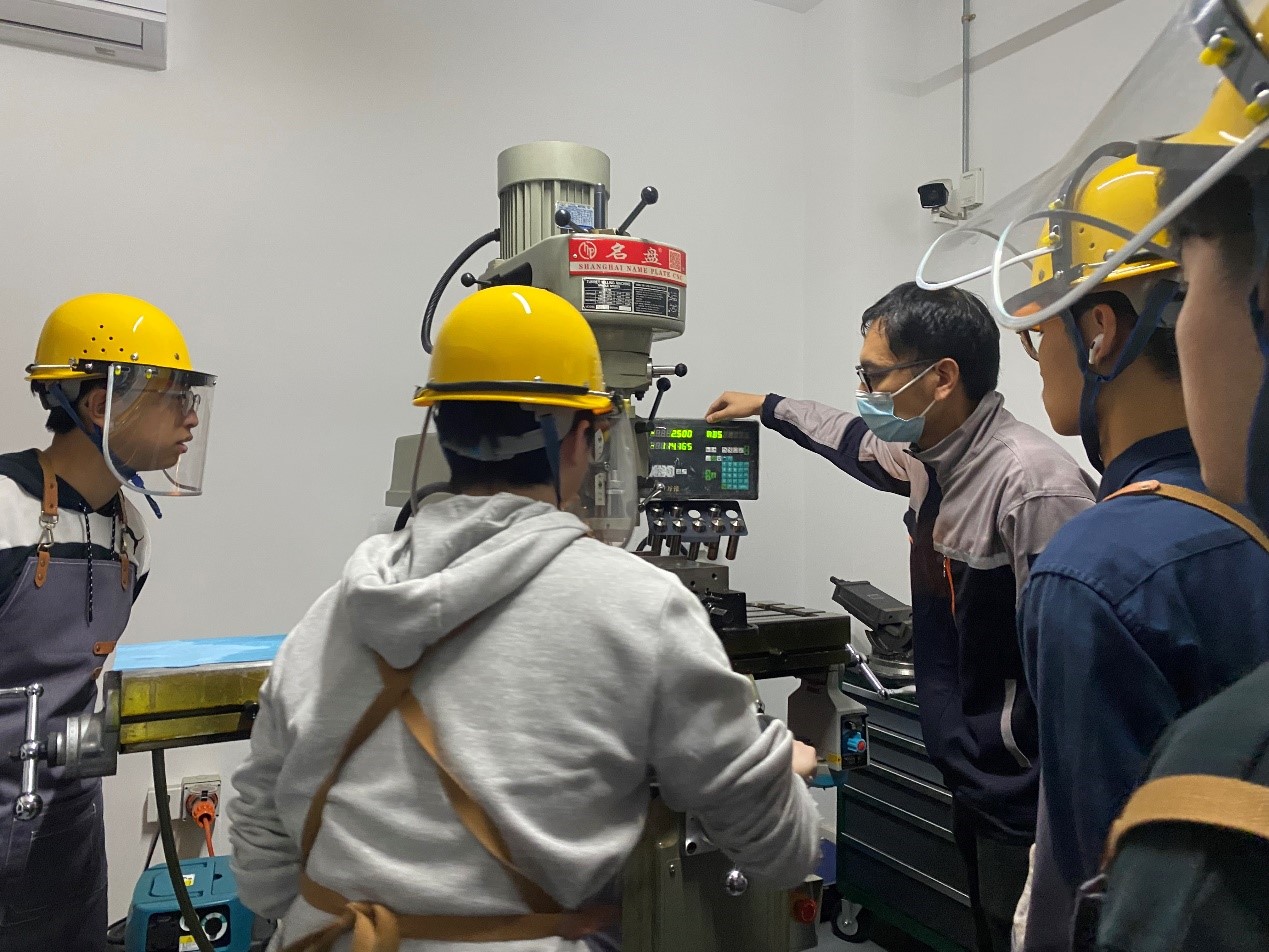

Manufacturing Processes (Instructor: Anand Prakash Dwivedi)

This course systematically builds the knowledge framework of the manufacturing field, guiding students from basic mechanical operations to complex creative designs, and from traditional techniques to cutting-edge Industry 4.0 technologies. Through hands-on practice, students evolve from passive recipients of knowledge into active explorers and creators.

The Mechanical Workshop (EMDC)

The course comprehensively covers fundamentals of material properties; casting, forming, machining, and joining processes; advanced manufacturing methods; as well as future trends like micromanufacturing and generative processes. Lab sessions focus on topics like engraving, electrical discharge machining (EDM), 3D printing, milling, CNC machining, welding, and drilling operations. Through a "learning-by-doing" approach, these experiments reinforce key concepts, helping students intuitively understand principles such as material behavior, precision machining, and process control.

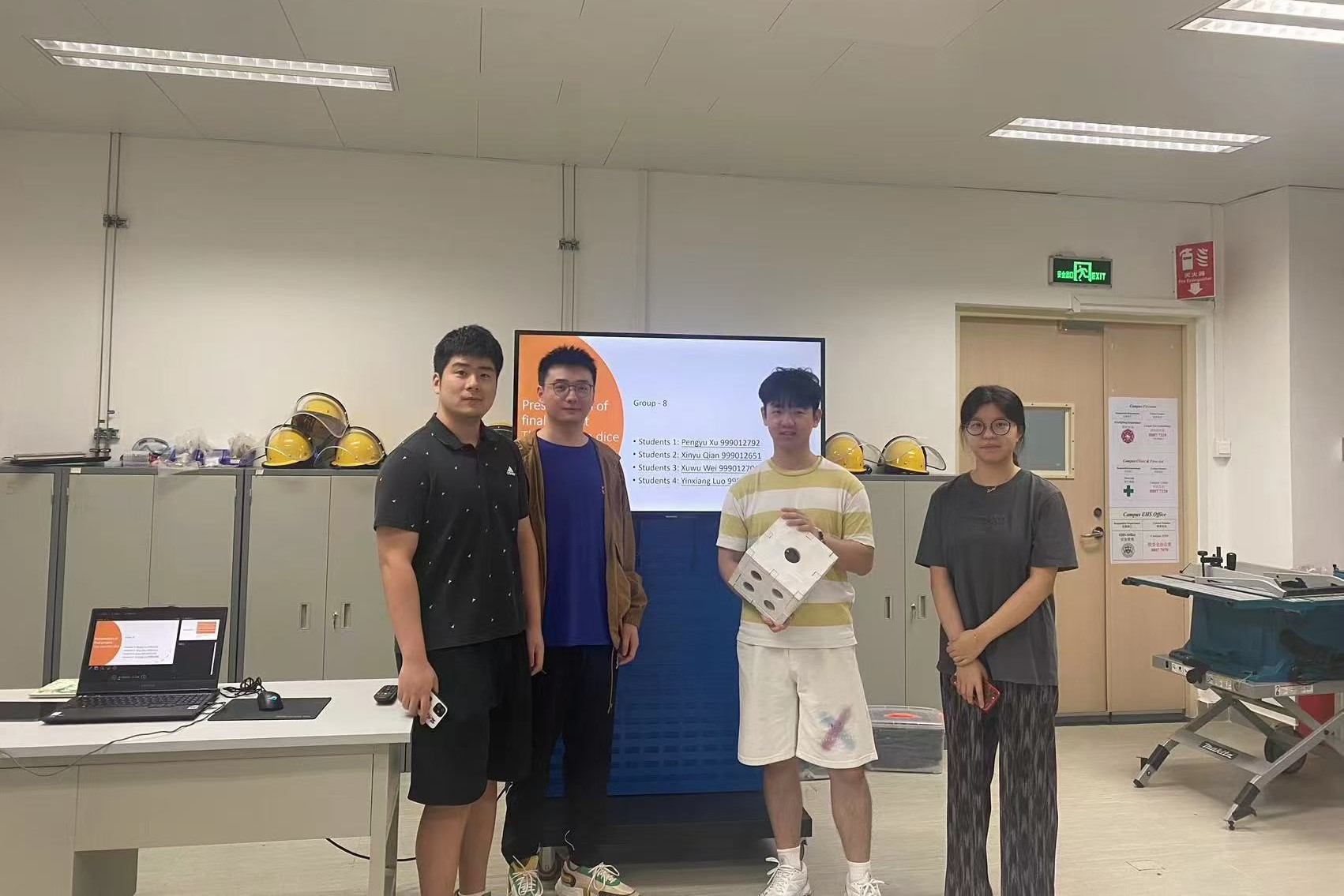

Students' Team Collaboration

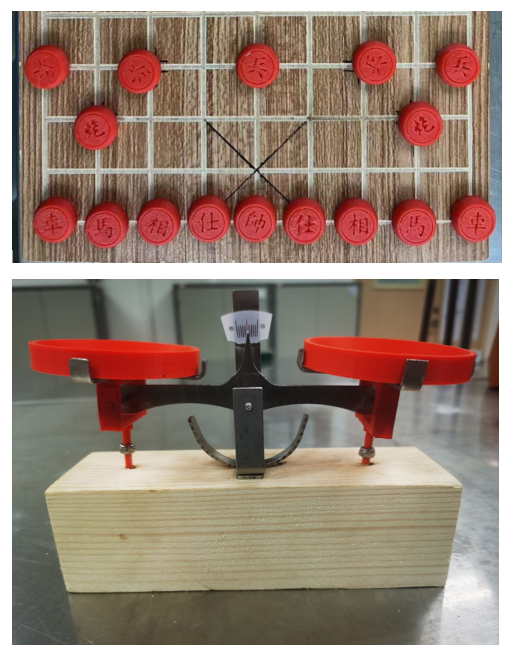

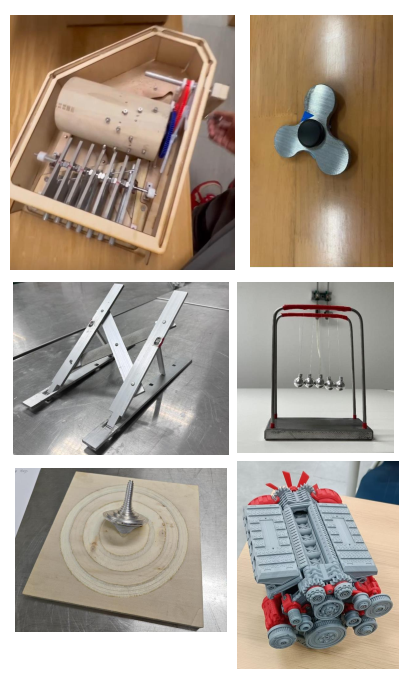

What makes the course unique is its problem-driven team project model. Working in groups of 4–5, students integrate three or more manufacturing processes (e.g., 3D printing + CNC machining + EDM) to design functional prototypes that address real-world engineering challenges. By applying interdisciplinary knowledge in materials science, mechanics, and process optimization, students present and defend their solutions in a final showcase.

Student Projects

This "theory-experiment-project" tripartite teaching approach enables students to gain hands-on experience with advanced equipment while simultaneously enhancing their capabilities in design and development, production planning, and teamwork. Whether sharing design concepts in presentations or transforming ideas into tangible prototypes in the lab, students consistently learn through creation, laying a solid foundation for future careers in robotics, automation, and smart manufacturing fields.

Course Project Presentations

This course is quite interesting. We explore various mechanical equipment and process workflows, and work in groups to complete the final project, gaining an understanding of the processes and principles of mechanical engineering through practice. The course cultivates our hands-on practical abilities, improves our social skills and collaborative problem-solving abilities through group work. More importantly, since the final project is entirely self-created, it also stimulates our innovative thinking. (Fan Xin, 23ME)

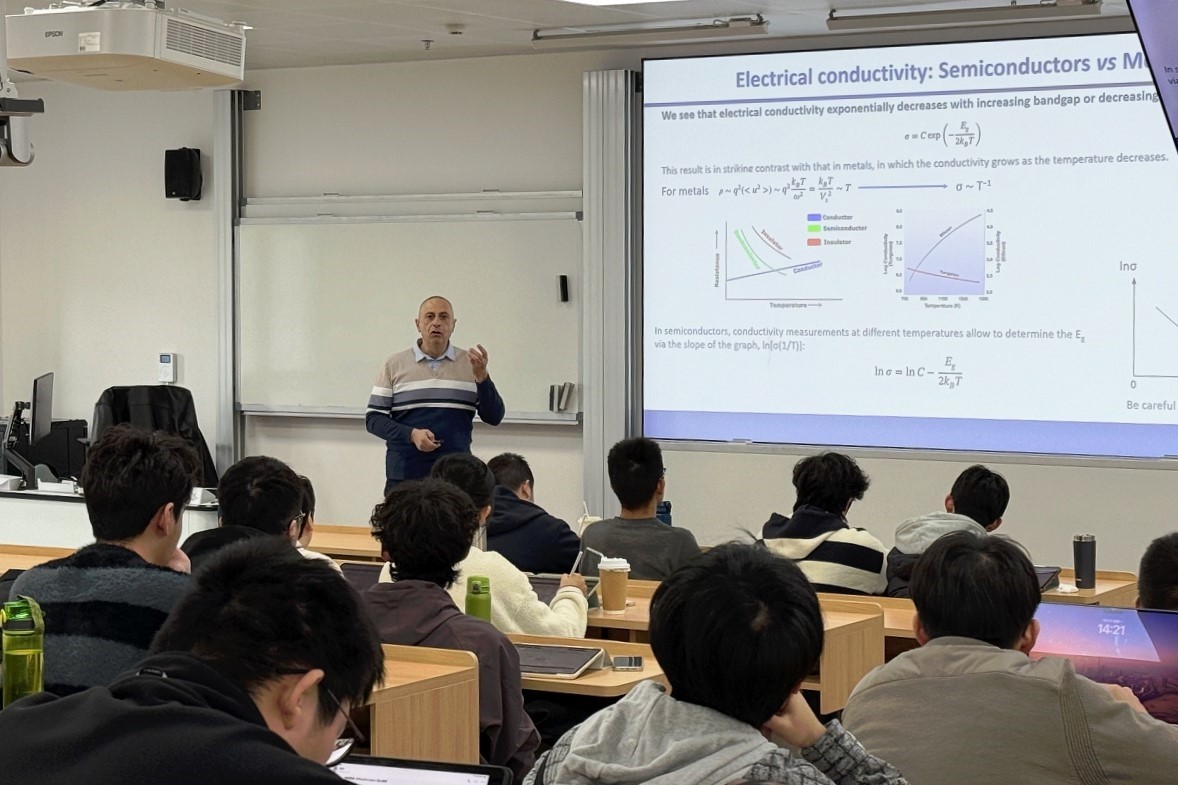

Solid State Physics (Instructor: Elissaios Stavrou)

From which material shall we use for cables and for cooking to how to make computers that can work both in north pole and deserts and how to understand superconductivity… Principles of solid-state physics are fundamental on explaining and understanding phenomena we encounter in everyday life. The course is mainly designed for third year MSE undergraduate students, systematically explaining the fundamental principles of solid-state physics, with a focus on phenomena related to materials.

The course seamlessly integrates everyday phenomena into the teaching process, helping students intuitively grasp abstract concepts and transforming seemingly profound solid-state physics knowledge into something learnable, tangible, and applicable. Why diamond is the best thermal conductor? Why metals are simultaneously good electrical and thermal conductors? Why electrically conductive of metals and insulators have opposite dependence with temperature? How technology advanced from heavy and energy consuming devices to today's light, energy efficient and small electronic devices? The students learn and understand the basic principles governing the properties of solids. Practical applications are highlighted, especially in connection with material science. These basic principles can be applied to almost any materials science problem they may face during their scientific career.

Solid State is a challenging course—it could arguably be called the most difficult in the materials science curriculum for me. However, the professor consistently uses vivid analogies and clear, accessible language to tackle complex topics, making even the most difficult concepts easier to grasp. The class is always dynamic, with a lively atmosphere and frequent discussions. Students are highly engaged and eager to interact with the professor. (Hu Shennan, 22 MSE)

When rigorous formulas come to life in experiments, and abstract theories take root in projects, we see how these courses, blending innovative ideas and practical wisdom, have become vital stepping stones on GTIIT students' path to professional growth. Moving forward, GTIIT will continue to set sail with cutting-edge technology as its compass, steer with the needs of the times, and chart new courses in the realm of science and engineering education.

Text/Photos: the interviewed faculty and students, GTIIT News & Public Affairs

© GUANGDONG TECHNION-ISRAEL INSTITUTE OF TECHNOLOGY | 粤ICP备17036470号